This winter, I set up my 2019 KTM 500 EXC-F as a snowbike. Riding and working on it has been considerably more fun than I could have imagined.

The past few times out, it has been bogging around 90% throttle and above. I'm new to working on dirt bikes, so I don't really know the cause. But, I've read that bogging near wide-open throttle can be an indication of fuel starvation. I have already replaced the fuel filter in the gas tank on this bike, which is a common weak point. So, today I decided to clean the fuel filter outside of the tank and clean the fuel injector.

Reading online, it seems that the two cleaning strategies are either to send your fuel injector to a professional to have it cleaned or to buy a tool to do it yourself. Part of the joy of owning this bike has been working on it, so I went the DIY route.

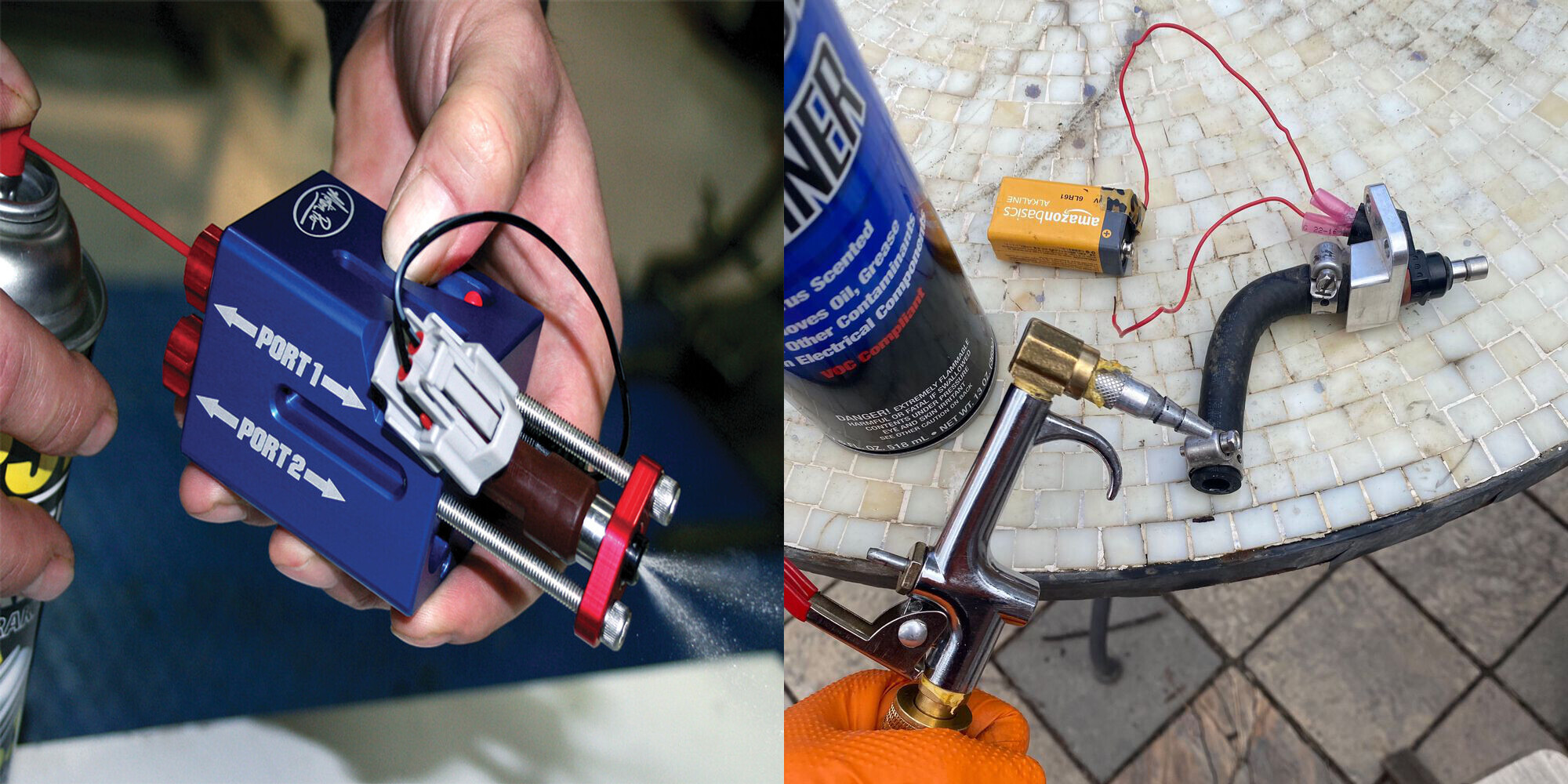

Normally, I don't mind spending money for the right tool for the job. "Buy once, cry once" is cliché but works. Although, I have been known to visit Harbor Freight to limit the number of tears I shed. From my brief research, the go-to (and maybe only?) tool for cleaning dirt bike injectors is the Motion-Pro Fuel Injector Cleaner Kit. It retails for about $160, and I would have to wait for it to be shipped to my house. Blugh, expensive for what amounts to a 9-volt battery, switch, and a holder to direct the cleaner into the fuel injector. I was hoping to solve this problem today. So, I went the DIY-DIY route and built one myself.

A perfectly hideous homebrew tool. The 22-18 AWG butt splice connectors slipped right over the prongs in the injector. They don't fit snugly, but they hang on well enough to get the job done. I used a 9-volt battery because that is what the Motion-Pro tool uses. They say not to hold the injector open for more than 3 seconds, presumably to not burn it out. The injector is used to being opened and closed rapidly, not being held open. The fuel system operates around 50 psi, so I set the regulator on my compressor to that. When power is applied to the injector, it opens and you can blow cleaner/air through it. I backflushed first and then blew out the direction fuel travels.

The tool worked like a charm, and I was able to flush some gunk out of the injector. In the process, I realized my fuel hoses were crumbling and definitely introducing little bits of rubber hose to the fuel. Of course, all downstream of the two fuel filters in the system.

I'll probably add a connector for the 9-volt and a switch to make things easier. But, I will miss the leopard duct tape.

There you go. If you're cheap, impatient, or both, like me, this will get the job done for a fraction of the cost of the professional tool.

For the programmers who read this article: That tool is a slapped-together shell script. I wouldn't hand it to someone else and tell them to use it, but it worked for me, and if you're careful, maybe it will for you too.